3D-Printed Plastic Beaker Could Be Key to Growing Algae on Mars

Scientists have designed a 3D-printed plastic beaker that may enable algae to grow under Martian conditions—potentially paving the way for life-support systems, food, and fuel production in future missions to the Red Planet.

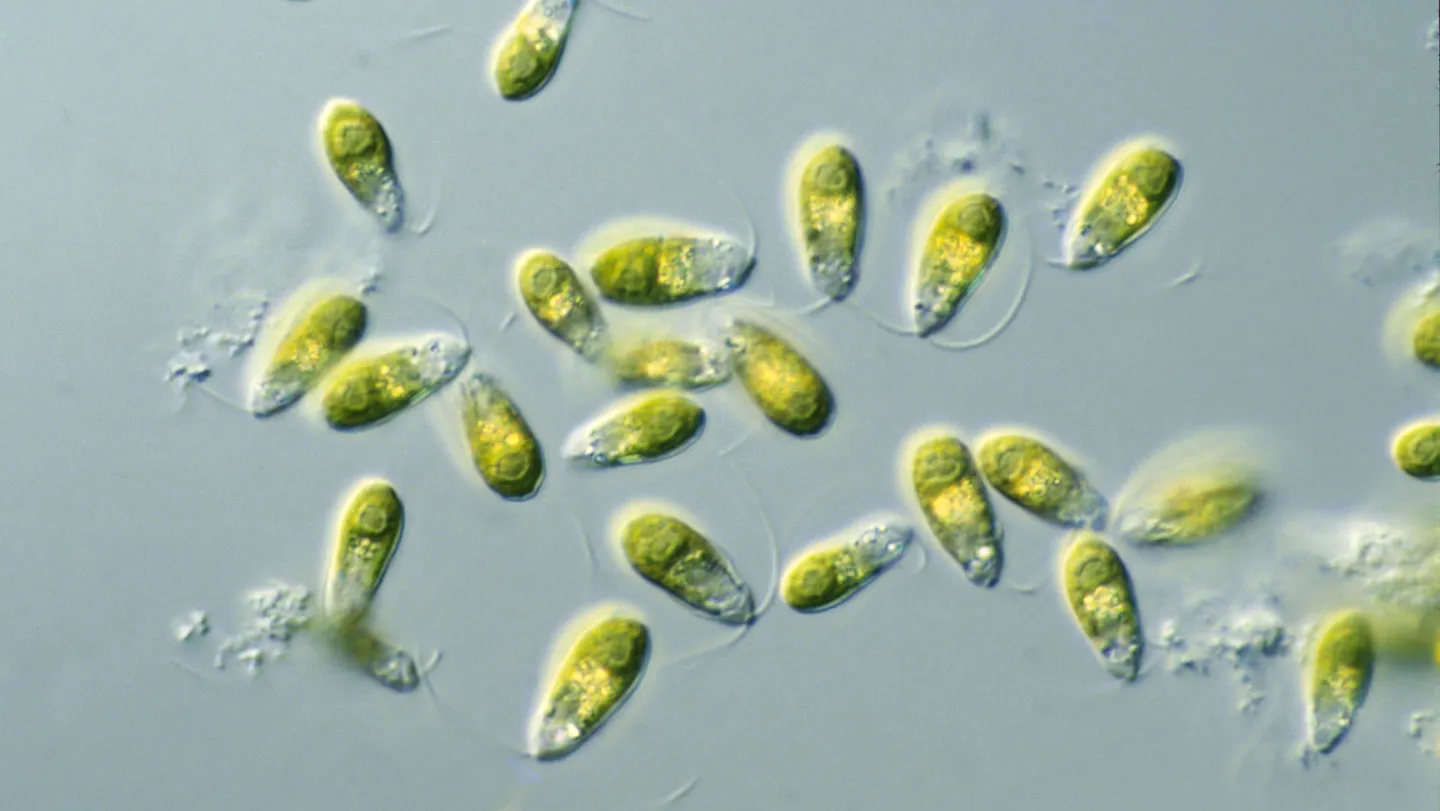

In a breakthrough that could influence how humanity survives beyond Earth, a team of scientists has developed a simple, 3D-printed plastic beaker that supports the growth of algae under simulated Martian conditions. This unassuming vessel may prove crucial in establishing sustainable life-support systems on Mars by enabling the cultivation of microorganisms that produce oxygen, food, and biofuel. Algae—tiny, photosynthetic organisms found in oceans and freshwater ecosystems—are gaining traction in astrobiology as a multi-functional lifeform.

Their ability to generate oxygen, recycle waste, and serve as a food source makes them ideal candidates for space habitats. But growing algae on Mars poses major challenges, including extreme temperatures, reduced sunlight, and an unbreathable atmosphere. That's where this innovative beaker comes in.

The Beaker That Could Build a Biosphere Created using readily available, biodegradable plastics and 3D-printing techniques, the beaker was designed by a research group at the University of Warwick in the UK, in collaboration with ESA (European Space Agency) researchers. The design is deceptively simple: a transparent, durable chamber capable of regulating gas exchange, humidity, and light exposure—factors crucial to photosynthesis. The team tested the beaker in a Mars simulation chamber, replicating low atmospheric pressure (about 600 pascals), high carbon dioxide levels, and light conditions comparable to the Martian surface.

Despite these harsh parameters, a resilient strain of algae known as *Chlorella vulgaris* not only survived—but thrived. “This beaker isn’t just a container,” said lead researcher Dr. Jessica Bainbridge.

“It’s a self-contained micro-habitat. It could serve as a modular unit for bioreactors on Mars. ” Why Algae? Algae have long been proposed as a vital component in closed-loop ecological systems for space travel and colonization.

Here's what they bring to the table:- Oxygen Production : Through photosynthesis, algae convert CO₂ and sunlight into oxygen—essential for astronauts in closed habitats. - Food Source : Algae are rich in protein, omega-3 fatty acids, and vitamins. Spirulina and *Chlorella* are already used in dietary supplements on Earth.

- Waste Recycling : Algae can process human waste products and convert them into biomass, reducing reliance on external supply chains. - Biofuel : Algal lipids can be converted into biofuel, offering a potential energy source on Mars. But realizing any of these benefits depends on whether algae can survive on Mars—or inside a habitat designed for Mars.

Simulating Mars: Harsh But Habitable? The Martian surface is a brutal environment. With average temperatures around -60°C, extreme radiation, and an atmosphere composed of over 95% CO₂, it offers few natural protections. Sunlight is weaker due to Mars' greater distance from the Sun and frequent dust storms, which can block solar rays for days or weeks.

That’s why the team focused on controlled, modular systems—like the beaker—that can simulate Earth-like conditions on a micro-scale. The 3D-printed beaker included features such as:- Gas-permeable walls for regulating internal CO₂ and O₂ concentrations - UV shielding layers to mimic Martian light without lethal radiation - Thermal insulation to maintain a viable temperature for algal metabolismOver a 30-day test period, algae maintained healthy growth curves, with biomass increasing by more than 70% under artificial Martian lighting. The 3D Printing Advantage One of the beaker’s most promising aspects is its printability.

If humanity reaches Mars, transporting bulky lab equipment will be logistically difficult and prohibitively expensive. But a small payload of biodegradable filament and a compact 3D printer could be used to manufacture hundreds of these vessels on demand. “This is about distributed science,” said Dr.

Bainbridge. “You could print dozens of these in situ, adjust the parameters, and run parallel experiments. It’s rapid prototyping for the Martian frontier.

”Moreover, the design files for the beaker are open-source and can be modified to test different strains of algae, bacteria, or even small plant seedlings. Scaling Up: From Beaker to Bioreactor The next step for the research team is scaling the system. While a single beaker can support milliliters of culture, a full-scale Mars mission would require hundreds of liters of biomass for oxygen and food production.

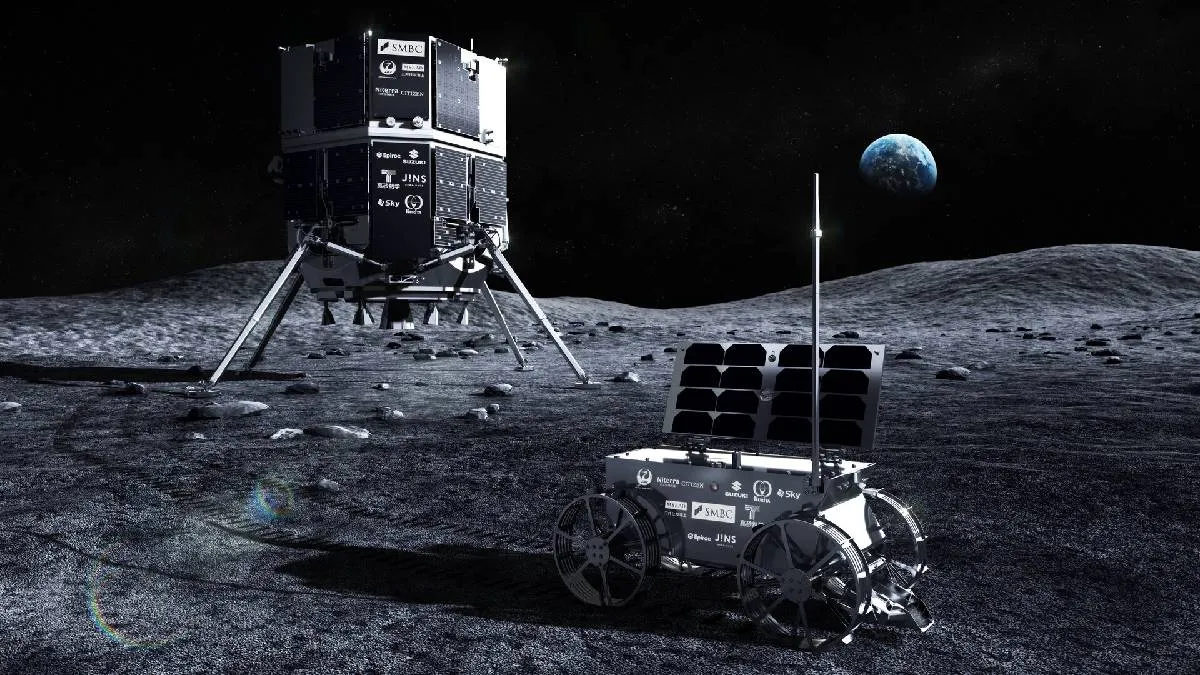

The team is working with ESA on developing stackable, modular algal bioreactors—essentially large arrays of these beakers, networked together and connected to life-support systems. Future versions may include automated light sensors, humidity controls, and even robotic harvesting arms. NASA is also exploring algae-based life-support systems through its Advanced Exploration Systems division, and the results of the Warwick study are feeding into a broader conversation about biological infrastructure on the Red Planet.

Implications Beyond Mars While designed with Mars in mind, the 3D-printed algae habitat has immediate uses on Earth:- Extreme Environment Research : Beakers can be deployed in Antarctic labs, deserts, or high-altitude stations. - Education : Schools can 3D print the system to run real-time biology experiments. - Food Security : Remote communities could grow algae for protein-rich food with minimal infrastructure.

Dr. Bainbridge’s team has already shipped prototypes to schools across Europe as part of ESA’s STEM outreach initiatives. The Broader Vision: Bioengineering for Planetary Survival This project aligns with a growing field known as “biological engineering for space settlement.

” As agencies and private companies like SpaceX, Blue Origin, and others lay plans for long-term space habitats, the role of biology is becoming increasingly central—not just as a support system, but as a form of architecture. Imagine entire Martian greenhouses filled with bioprinted vessels, each nurturing life. Or algae-based walls that double as both insulation and oxygen generators.

These are no longer science fiction scenarios—they are beginning to take shape in laboratory models. Challenges Ahead While promising, the beaker system still faces key hurdles:- Radiation Shielding : Long-term exposure to cosmic radiation could damage algal DNA unless protected underground or with additional shielding. - Nutrient Sources : Mars lacks bioavailable nitrogen and phosphorus—essential for algae—so recycling and supplement strategies must be devised.

- Contamination Risks : Closed-loop systems must be meticulously sterile to prevent competing microbes from disrupting the culture. ESA and NASA are conducting longer-duration tests and planning to launch beaker prototypes aboard CubeSats and space station platforms to observe their behavior in microgravity. Conclusion: A Small Container with Planetary Potential The 3D-printed algae beaker is more than a piece of plastic—it’s a symbol of how low-cost, adaptable design can unlock high-impact possibilities for life on Mars and beyond.

By enabling a humble microorganism to survive off-Earth, scientists are laying the groundwork for biological infrastructure that could support future explorers and settlers. From oxygen and food to energy and ecosystem services, algae may be the unsung hero of interplanetary survival. And it all might start with a tiny printed cup, glowing green in the red dust of Mars.

8th July 2025